Comparison of Spire RO profiles Processed by UCAR and Spire

Vladimir

Irisov

Spire Global

Poster

Spire Global operates more than 100 3U CubeSats in various low Earth orbits. Each satellite is equipped with a GNSS receiver capable of collecting more than 1,000 radio occultation (RO) profiles per day from GPS, GLONASS, Galileo, and QZSS constellations. Currently, Spire collects more than 12,000 profiles daily, of which approximately 10,000 result in inverted RO profiles that pass quality control (QC).

From mid-December 2020 to mid-January 2021, Spire supplied RO profiles in the first delivery order of the NOAA Commercial Weather Data Operational Buy. During the 30-day period Spire delivered 700 profiles per day derived from GPS and GLONASS transmissions. The Spire RO data were collected from 17 different satellites in a variety of orbits and characterized by a mean SNR of about 400 V/V at 1 s, median bending angle noise of about 1.4-1.5 urad, mean latency time of about 85 minutes, and close to a uniform global distribution. Before delivery to NOAA, each profile was processed in near real-time by Spire and passed internal quality control. Post-processing of each profile was performed by UCAR from raw (level 0) measurements. This is the first time Spire has had the opportunity to compare its processed RO profiles to those produced by an external processing center.

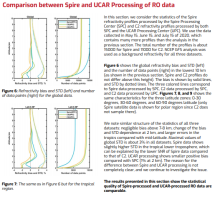

Here, we will compare the statistics of penetration depth, bending angle, and refractivity against background evaluated from ECMWF gridded analysis. We also investigate the effect of the different profile geolocation definitions. In general, we find the difference between the quality of processed profiles is small, but that UCAR’s QC differs from that of Spire by rejecting some of the profiles that pass Spire QC. This type of comparison highlights differences among processing centers and helps to encourage more common and improved processing techniques by all centers.

From mid-December 2020 to mid-January 2021, Spire supplied RO profiles in the first delivery order of the NOAA Commercial Weather Data Operational Buy. During the 30-day period Spire delivered 700 profiles per day derived from GPS and GLONASS transmissions. The Spire RO data were collected from 17 different satellites in a variety of orbits and characterized by a mean SNR of about 400 V/V at 1 s, median bending angle noise of about 1.4-1.5 urad, mean latency time of about 85 minutes, and close to a uniform global distribution. Before delivery to NOAA, each profile was processed in near real-time by Spire and passed internal quality control. Post-processing of each profile was performed by UCAR from raw (level 0) measurements. This is the first time Spire has had the opportunity to compare its processed RO profiles to those produced by an external processing center.

Here, we will compare the statistics of penetration depth, bending angle, and refractivity against background evaluated from ECMWF gridded analysis. We also investigate the effect of the different profile geolocation definitions. In general, we find the difference between the quality of processed profiles is small, but that UCAR’s QC differs from that of Spire by rejecting some of the profiles that pass Spire QC. This type of comparison highlights differences among processing centers and helps to encourage more common and improved processing techniques by all centers.

Poster PDF